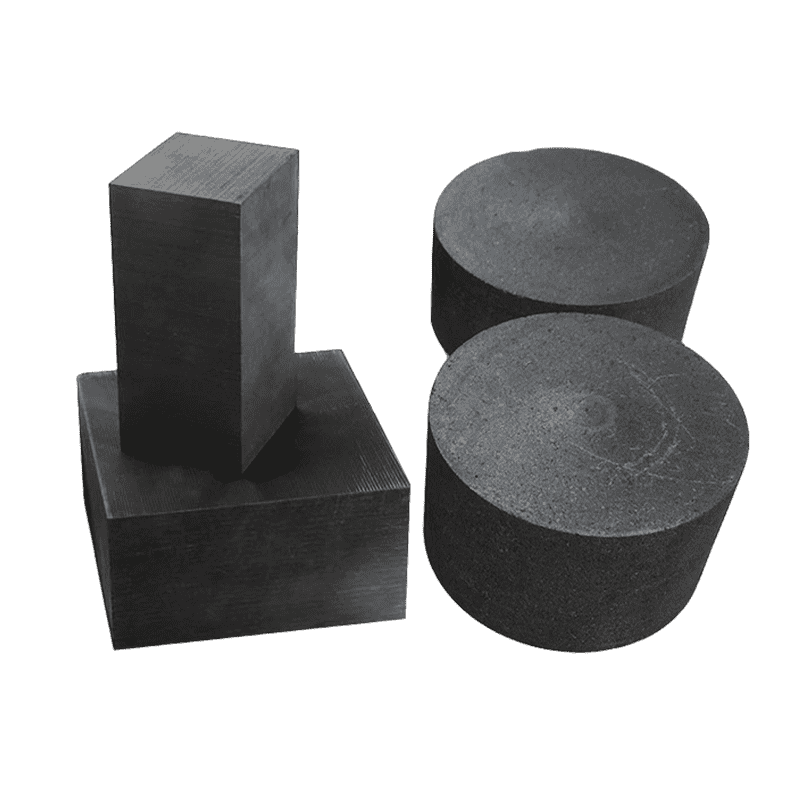

Our graphite processing parts are a series of high quality graphite products made of high purity graphite materials, including graphite blocks, graphite crucibles, graphite rods (electrode bars, graphene) and graphite plates. We adopt the most advanced production technology and equipment to ensure the quality and stability of these products. Meanwhile, we also provide personalized custom services and produce customized products according to our customers' production needs.

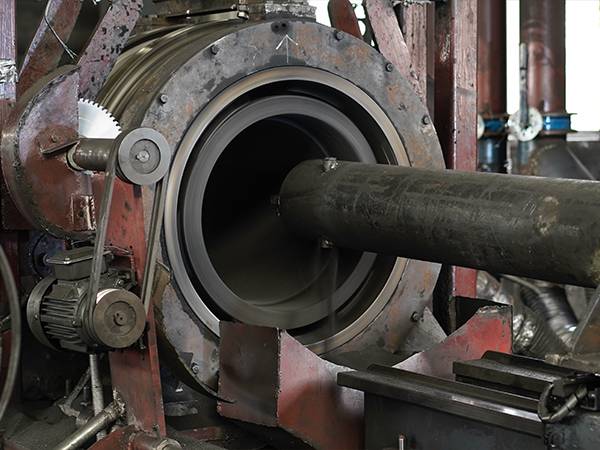

These products have excellent high temperature resistance, corrosion resistance and electrical & thermal conductivity, and are widely used in power, metallurgy, chemical, mechanical and other industries.

- Extreme high thermal resistance and chemical resistance.

- High purity, high electrical and thermal conductivity.

- Excellent thermal shock and oxidization resistance.

- Good corrosion resistance and high temperature resistance.

- Good self-lubrication and chemical stability.

- High mechanical strength and can be used for precision machining.

Our graphite special-shaped parts can be used for various kinds of product machining.

| Model | Density (g/cm3) | Particle Size (μm) | Specific Resistance (μΩ.m) | Porosity | Shore Hardness | Compressive Strength (MPa) | Flexural Strength (MPa) | CTE (× 10-6 °C-1) | Application |

|---|---|---|---|---|---|---|---|---|---|

| IS-2(Isostatic) | 1.76 | 20 | 15 | 20% | 60 | 95 | 50 | 5.9 | Heat exchanger/all kinds of machining |

| IS-3(Isostatic) | 1.85 | 10 | 12 | 13% | 48 | 85 | 46 | 4.3 | Sintering/all kinds of machining |

| IS-4(Isostatic) | 1.90 | 5 | 12 | 13% | 48 | 85 | 46 | 4.3 | Sintering/all kinds of machining |

| ED-1(Isostatic) | 1.83 | 9 | 12 | 12% | 65 | 116 | 51 | 5.8 | EDM, semi finishing/finishing |

| ED-2(Isostatic) | 1.81 | 7 | 12 | 12% | 69 | 135 | 62 | 6.8 | EDM, semi finishing/finishing |

| ED-3(Isostatic) | 1.90 | 5 | 12 | 12% | 69 | 135 | 62 | 6.8 | EDM finishing,ultra fine grain for low electrode wear |

| ED-4(Isostatic) | 1.92 | 3 | 11 | 11% | 72 | 160 | 69 | 6.9 | EDM finishing, lowest electrode wear |

| MD-1(Molded) | 1.78 | 25 | 12 | 20 | 48 | 80 | 40 | 5 | Sintering/all kinds of machining |

| MD-2(Molded) | 1.72 | 25 | 12 | 19 | 45 | 60 | 32 | 5 | Sintering/all kinds of machining |

| MD-3(Molded) | 1.56 | 25 | 12 | 23 | 35 | 38 | 16 | 5 | Sintering/all kinds of machining |

| GE-1 | 1.72 | 0.8/2.0 | 7.5 | – | – | 35 | 14 | 2.4 | Electrode/rotors & shafts |

| GE-2 | 1.60 | 0.8/2.0 | 9.5 | – | – | 25 | 10 | 2.9 | Electrode/rotors & shafts |

| MC-0(Extruded) | 1.75 | 0.8/2.0 | 9 | – | – | 40 | 18 | 2.5 | Heat exchanger/heater |

| MC-1(Extruded) | 1.74 | 0.8/2.0 | 9 | – | – | 38 | 16 | 2.3 | Heat exchanger/heater |

| MC-2(Extruded) | 1.70 | 0.8/2.0 | 10 | – | – | 29 | 12 | 2.3 | Heat exchanger/heater |

| MC-3(Extruded) | 1.68 | 0.8/2.0 | 10 | – | – | 18 | 8 | 2.3 | Heat exchanger/heater |

| File Name | Last Update | File Size | Download |

|---|---|---|---|

| File Name: Graphite Processing Part Data Sheet | Last Update: 2023.7.14 | File Size: 2.09 MB | Download: |