Graphite electrode wastes are residues generated in the process of machining or using graphite electrode. These scraps mainly come from 2 sources. One is the leftover scraps generated in the process of machining graphite electrodes, while the other is the wastes generated in the process of steelmaking process or the broken fragments generated during use.

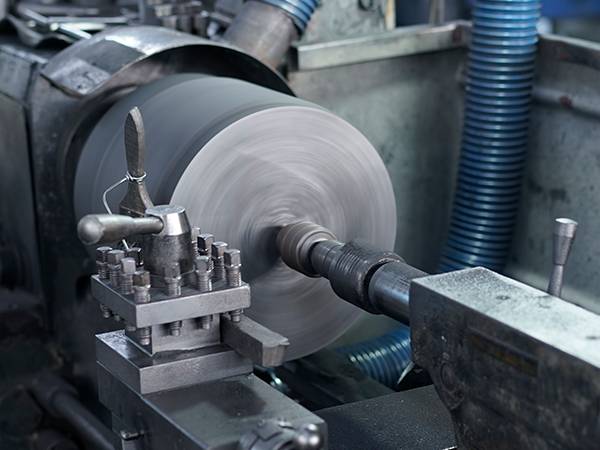

Graphite electrode wastes can be recycled and reused. Generally, they are used to machine graphite products, such as graphite crucibles and graphite parts, or are crushed into powder for recycled electrode production.

- High purity, low resistance.

- High temperature resistance, corrosion resistance.

- Excellent electrical & thermal conductivity.

- Good oxidization resistance, thermal shock resistance.

- High machining precision.

| File Name | Last Update | File Size | Download |

|---|---|---|---|

| File Name: Graphite Processing Part Data Sheet | Last Update: 2023.7.14 | File Size: 2.09 MB | Download: |